How Digital Twins Are Revolutionizing Industrial Operations

Digital twins represent a significant advancement in industrial operations, merging physical and digital realms through real-time data integration. These virtual replicas enable industries to conduct predictive maintenance and optimize processes with simulations. As organizations increasingly adopt this technology, the impact on operational efficiency becomes evident. However, understanding the full scope of applications and benefits requires a closer examination of both current practices and emerging trends in digital twin technology.

Understanding Digital Twins: Definition and Key Components

Digital twins represent a transformative paradigm in industrial operations, characterized by their ability to create virtual replicas of physical assets.

A digital twin overview encompasses essential core components such as real-time data integration, advanced analytics, and simulation capabilities.

These elements facilitate an accurate representation of physical systems, enabling organizations to optimize performance, enhance decision-making, and ultimately achieve greater operational freedom in a dynamic industrial landscape.

See also: How Digital Twins Are Changing the Way We Design and Build

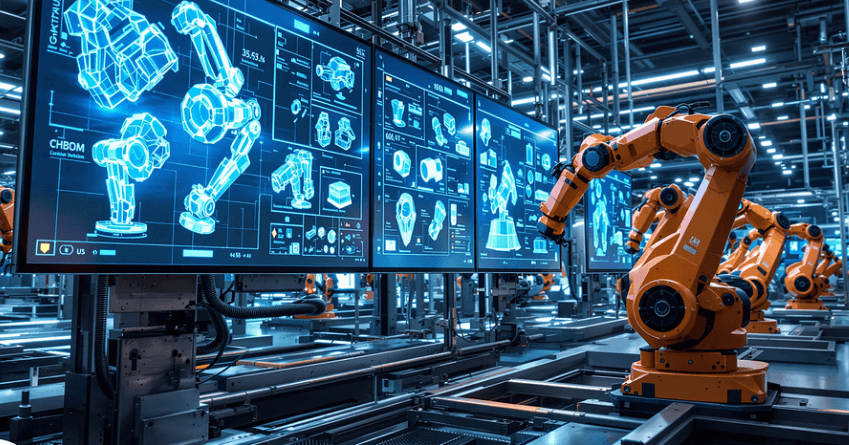

Applications of Digital Twins in Industrial Settings

As industries increasingly adopt advanced technologies, the applications of digital twins in industrial settings have become pivotal for enhancing operational efficiency and innovation.

These technologies facilitate predictive maintenance by analyzing real-time monitoring data, allowing for timely interventions before failures occur.

Additionally, digital twins support optimization of processes through simulations, enabling enhanced decision-making and resource allocation in complex industrial environments.

Benefits of Implementing Digital Twins for Operational Efficiency

Implementing digital twins significantly enhances operational efficiency across various industrial sectors, primarily through improved data integration and analysis.

These virtual replicas enable real-time monitoring and predictive maintenance, reducing downtime and associated costs. As a result, organizations experience significant cost savings while optimizing resource allocation.

The integration of digital twins facilitates informed decision-making, ultimately driving productivity and enhancing overall operational performance.

Future Trends and Innovations in Digital Twin Technology

The evolution of digital twin technology is poised to reshape industrial operations further, driven by advancements in artificial intelligence, machine learning, and Internet of Things (IoT) integration.

Future innovations will enhance predictive analytics capabilities, allowing for proactive decision-making.

Additionally, real-time monitoring will enable more responsive operational adjustments, ultimately leading to increased efficiency, reduced downtime, and improved resource management in complex industrial environments.

Conclusion

In the realm of industrial operations, digital twins emerge as a lighthouse, illuminating the path toward enhanced efficiency and innovation. By mirroring physical assets, they provide a compass for predictive maintenance and data-driven decision-making, guiding industries through turbulent waters. As organizations embrace this transformative technology, they cultivate a fertile ground for growth, ensuring resilience against future challenges. Ultimately, the integration of digital twins symbolizes a new dawn of operational excellence, poised to redefine the landscape of industrial practices.